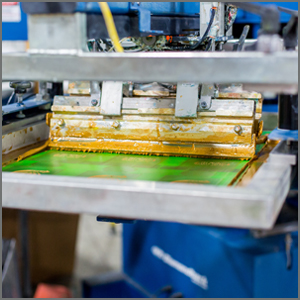

Screen Print (for one color foam and one color business pulpboard)

- The screen printing process burns the desired imprint into a screen that is then placed on top of the product material as the ink is pushed through. The ink is then transferred onto the material in the shape of the image or design.